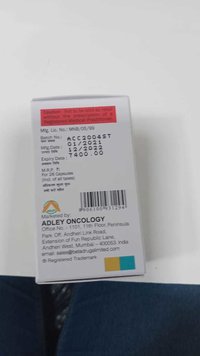

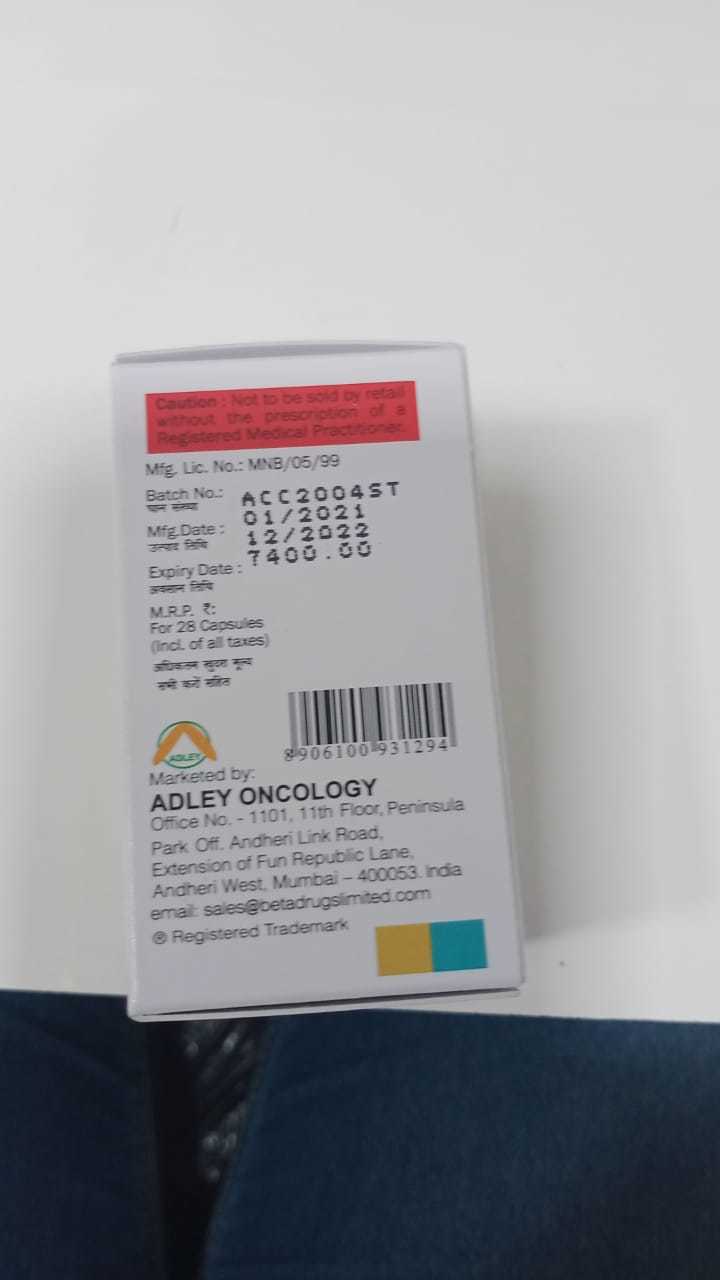

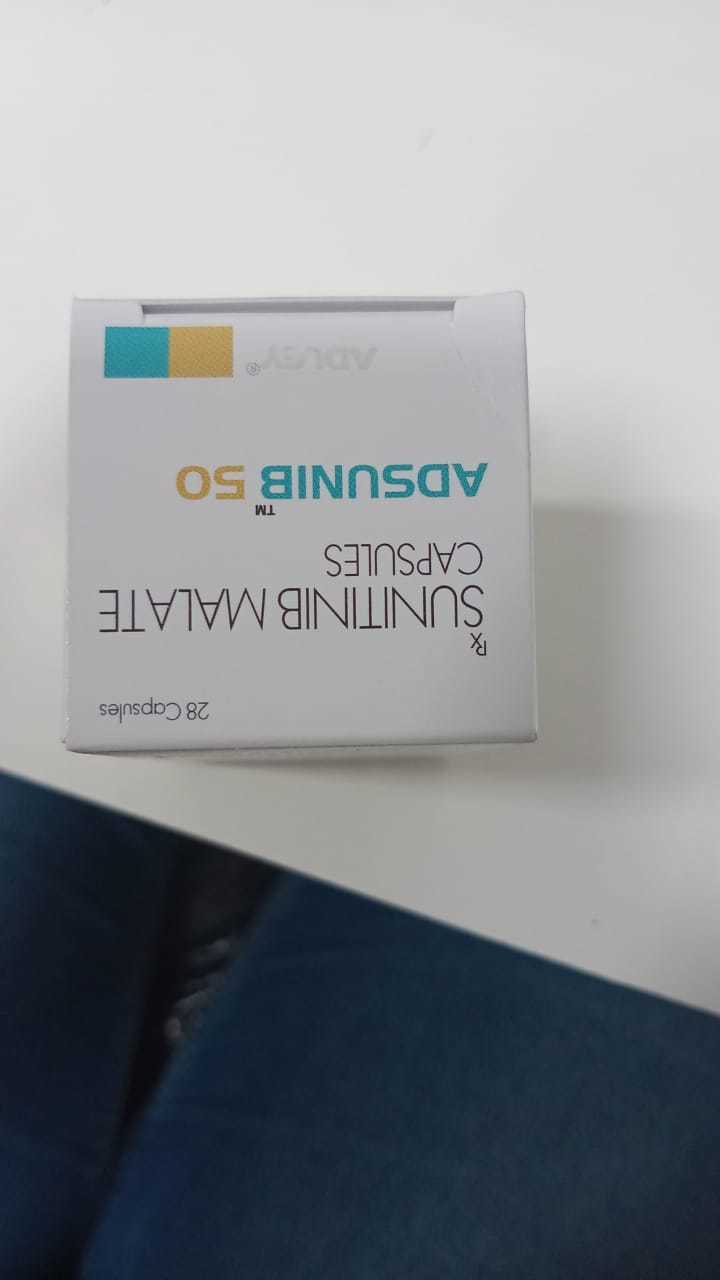

Adsunib 50

7400 INR/Dozen

Product Details:

- Salt Composition Fungal Alpha Amylase 50,000 U/g (Aspergillus oryzae)

- Indication For Starch Conversion, Brewing, Distillery, and Baking

- Dosage Form Powder

- Enzyme Types Alpha Amylase

- Feature High Enzymatic Efficiency

- Ingredients Fungal Alpha Amylase, Maltodextrin

- Application Other

- Click to View more

X

Adsunib 50 Price And Quantity

- 7300.00 - 7400.00 INR/Dozen

- 1-50 Gram

- 7400 INR/Dozen

Adsunib 50 Product Specifications

- 12 months

- 5.56.5

- For Starch Conversion, Brewing, Distillery, and Baking

- Fungal Alpha Amylase 50,000 U/g (Aspergillus oryzae)

- High Enzymatic Efficiency

- Alpha Amylase

- Fungal Alpha Amylase, Maltodextrin

- Mild Enzymatic Odor

- Store in a cool and dry place, away from sunlight

- 50,000 Units per gram (U/g)

- Other

- Powder

- 5060C

- Off White Powder

Adsunib 50 Trade Information

- Cash on Delivery (COD), Cash Against Delivery (CAD), Cash in Advance (CID), Cheque, Cash Advance (CA)

- South America, Eastern Europe, Western Europe, Central America, Asia, North America, Australia, Africa

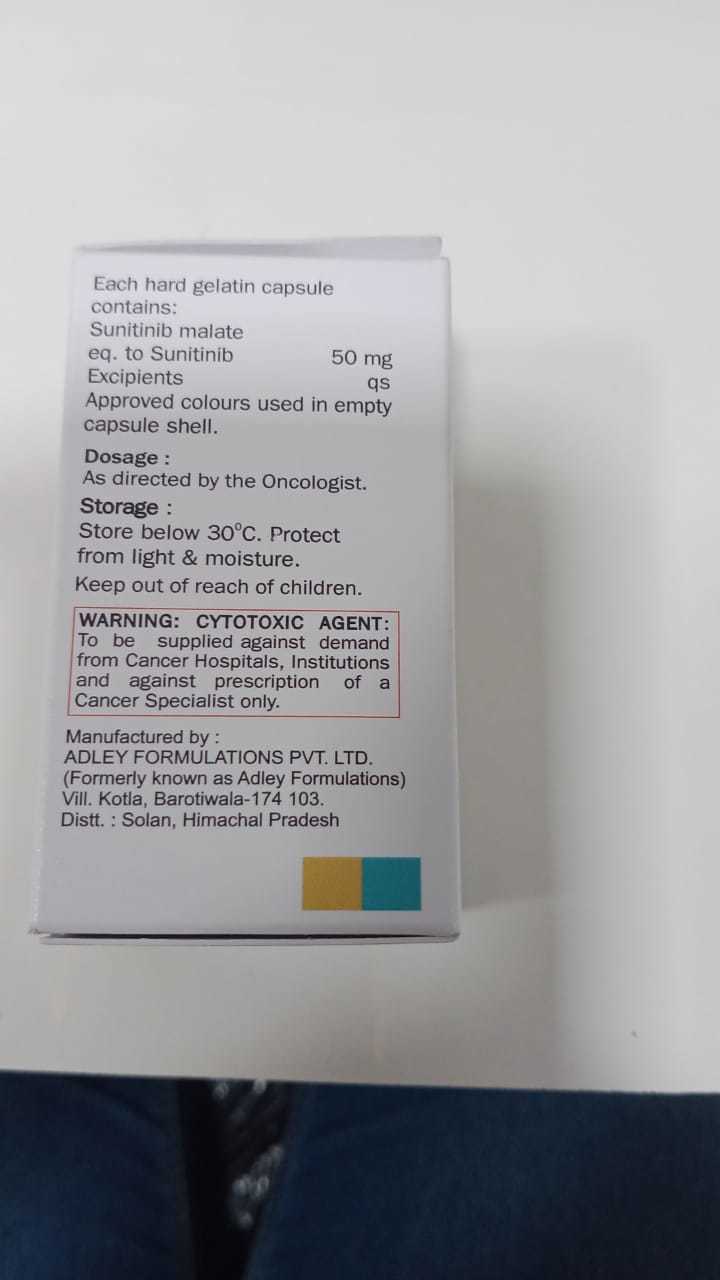

- Your healthcare provider may prescribe medicine for you to treat high blood pressure, if needed. Your healthcare provider may temporarily stop your treatment with SUTENT until your high blood pressure is controlled

Product Description

Adsunib 50

Its important to remember to take SUTENT as directed by your doctor. Do not change your dose or stop taking SUTENT without first talking with your doctor. Your doctor may change how you take SUTENT or tell you to stop taking SUTENT

Reliable Enzyme Solution for Industry

Adsunib 50 is designed for distributors, exporters, and manufacturers in the food and fermentation sector. Its advanced fungal alpha amylase formulation delivers robust starch conversion and high enzymatic activity suitable for large-scale baking, brewing, distillery, and fermentation processes. With thorough quality control and adherence to food-grade standards, Adsunib 50 supports both efficiency and product safety in commercial production.

Key Features and Dosage Flexibility

The product's complete solubility and high purity (above 97%) make it easy to incorporate into a variety of processes. Delivered as an off-white powder with a shelf life of 12 months, Adsunib 50 ensures consistent performance and stability. Its efficient enzymatic activity at standard fermentation conditions (pH 5.5-6.5, 50-60C) allows for precise control and effective starch hydrolysis in both batch and continuous operations.

FAQ's of Adsunib 50:

Q: How is Adsunib 50 used in industrial fermentation processes?

A: Adsunib 50 is added directly to starch-containing substrates during industrial fermentation to catalyze starch breakdown into simpler sugars. This enhances fermentable sugar availability, supporting efficient yeast or microbial growth and promoting high yields in brewing and distillation.Q: What are the benefits of using Adsunib 50 in baking and brewing?

A: In baking, Adsunib 50 improves dough handling and loaf volume by efficiently converting starch to sugars, which the yeast consumes. In brewing, it increases fermentable sugar content, promoting better alcohol yields and more consistent product quality.Q: When should Adsunib 50 be added during the production process?

A: Adsunib 50 should be introduced at the starch conversion stage during fermentation, typically when substrate temperature is between 50-60C and pH is maintained at 5.5-6.5 for optimal enzymatic activity.Q: Where should Adsunib 50 be stored to maintain its efficiency?

A: To preserve its enzymatic activity, Adsunib 50 should be kept in a cool and dry location, away from direct sunlight and moisture. Proper storage ensures its high efficacy is retained throughout its 12-month shelf life.Q: What is the process for incorporating Adsunib 50 into industrial recipes?

A: Dissolve the required dose of Adsunib 50 powder in water and mix evenly with the substrate. Follow your specific process's temperature and pH guidelines to guarantee optimum enzymatic action during starch conversion.Q: How does Adsunib 50's high purity and enzymatic strength benefit industrial users?

A: With above 97% purity and activity at 50,000 U/g, Adsunib 50 enables effective starch conversion at lower usage rates, reducing processing time and cost while increasing output and consistency.Q: Is Adsunib 50 suitable for food-grade applications in different industries?

A: Yes, Adsunib 50 is a food-grade enzyme tailored for use in baking, brewing, and industrial fermentation, meeting safety and efficiency standards required for food processing.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Anti Cancer Tablets' category

|

DISTINCT LIFECARE

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese